The best water-based paint stripping pumps

Water-based paint stripping is a technique increasingly used in a variety of industries due to its ability to remove paints and coatings without the use of harsh chemical solvents. This method harnesses the power of water at very high pressure to detach paint from surfaces, minimizing environmental impact and providing fast and effective results. However, to achieve optimal results, it is essential to use machinery equipped with quality high-pressure pumps.

With this article, we at Hawk will explore the importance of piston pumps in the water-based paint stripping process and the main factors to consider when choosing them, with a focus on some of the best pumps available on the market.

The importance of pumps in the paint stripping process.

Pumps are the heart of the water-based paint stripping process. They are responsible for generating the pressure needed to effectively remove paints, even the toughest ones, from surfaces. Without sufficient pressure, the process could take much longer and would be ineffective on particularly hard or complex surfaces. A high-quality pump not only provides high performance, but also ensures longer life and reduced downtime, making the entire process more efficient and less costly in the long run. In addition, a well-calibrated pump reduces the risk of damaging surfaces, providing a powerful but controlled action.

Factors to consider when choosing a pump

When choosing a water-based paint stripping pump, there are several factors to consider to make sure you get the most out of your investment. Here are the main ones:

- Pressure: One of the key elements is the pressure generated by the pump. For paint stripping, it is generally recommended to use pumps with a pressure of 1000 bar or more. This pressure is sufficient to remove particularly tough paints without compromising the safety of the operator or damaging the surface being treated.

- Water flow rate: the amount of water the pump is able to deliver per minute (l/min) directly affects the speed of the process. A higher flow rate allows larger areas to be covered in less time, making the process faster and more efficient.

- Materials of construction: pumps must be made of materials suitable for withstanding the high pressures involved.

- Ease of maintenance: pumps that require little maintenance or are easy to maintain can reduce downtime and operating costs. Opting for models that allow quick replacement of wear parts can make a difference.

Hawk's best pumps for water-based paint stripping

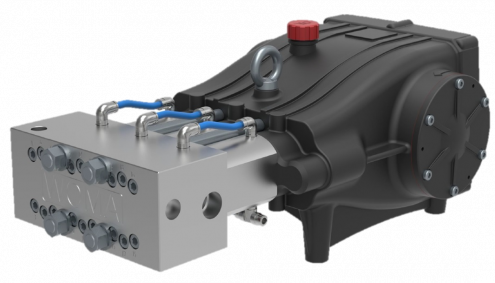

Hawk is a brand renowned for manufacturing quality high-pressure pumps that are ideal for the water-based paint stripping process. Two models in particular stand out for their performance and reliability: the GXX Series and TXX Series.

- GXX Series pump: this pump offers exceptional power, with pressures up to 1000 bar and a flow rate of up to 24 l/min. With its rugged stainless steel construction, the GXX Series is ideal for industrial applications requiring high performance and durability. Its compact size and ability to maintain constant pressure make it perfect for intensive paint stripping operations.

- TXX Series pump: with a maximum pressure of 1000 bar and a flow rate of up to 30 l/min, the TXX Series is currently the most powerful solution in the Hawk range. This pump is particularly suitable for removing extremely tough paints and coatings. Its robust design and the high-quality materials used in its construction make it a safe choice for those who need a reliable pump for demanding applications.

Conclusions

In conclusion, choosing the right pump for water-based paint stripping is critical to ensuring an effective, safe and long-lasting process. A quality high-pressure pump, such as those offered by us at Hawk, ensures optimal performance while minimizing downtime and maintenance costs.

If you need assistance choosing the right pump for water-based paint stripping, contact us today! Our team of experts is here to help you find the perfect solution for your industrial needs.

Share this Article