Chemical

Hawk produces a wide range of pumps with pressures and flow rates that meet the majority of high-pressure cleaning needs. In some situations however, clean water at high pressure may not be sufficient for effective cleaning. In these cases, there are 2 possible solutions: The first is to use plenty of chemical products, which have greater impact on the environment but use less energy. The second is to use a very high cleaning pressure but without the use of chemicals, but this solution involves a greater use of energy. We have come up with a solution that combines both aspects, a series of products that offer a satisfactory pressure level, but at the same time also work with chemicals that are not normally accepted by the most common pressure pumps on the market.

The type of application we are considering concerns the internal cleaning of a certain type of containers normally used in production processes or for transporting various substances, including plastic or steel bins, jerry cans and cisterns, silos, tanks or chemical reactors. All these cases refer to the cleaning of surfaces contaminated with substances that are particularly difficult to remove, such as water-resistant paints, resins or glue residues in the chemical industry. Clean water is not alone enough to remove this type of substances, but some liquids can be more effective, each for a specific purpose: demineralised water, caustic soda, or some acids or solvents.

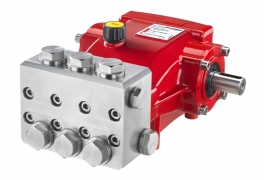

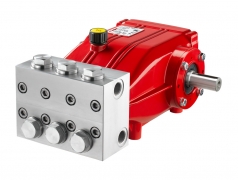

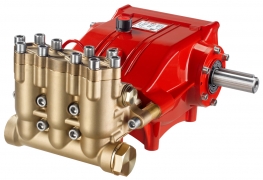

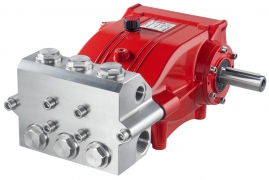

Hawk: high pressure chemical pumps

Hawk supplies a series of chemical pumps that use materials compatible with aggressive fluids, such as Ecobrass which is ideal for demineralised water and solvents or stainless steel INOX 316L which can work with acids and caustic soda. Various types of fluids have been tested in our laboratories, confirming the high compatibility with the materials selected for the pump design.