What will be the future progress of piston pumps?

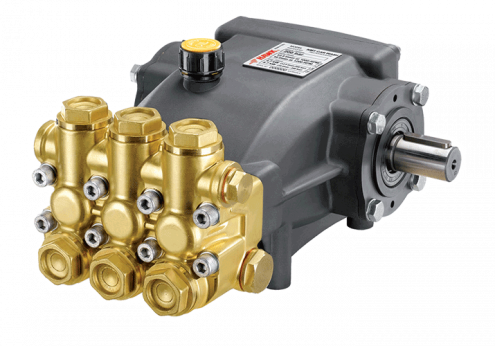

Piston pumps represent one of the most established and widespread technologies in the industrial and hydraulic sectors due to their ability to handle high pressures and significant volumes of liquid. As technology advances, we expect significant advances in piston pumps that will revolutionize their use in various industries.

With this article, we at Hawk will explore possible trends that could shape the future of piston pumps.

Advanced materials

The use of innovative and durable materials will increase the performance of piston pumps. Lightweight alloys and composite materials that can resist wear and tear will be used, improving efficiency and reducing weight. These new materials will reduce not only maintenance costs but also the energy required to operate the pumps. Components with self-lubricating surfaces will be developed, further lowering internal friction and extending the life of moving parts.

Energy Efficiency

Pumps of the future will be designed to optimize energy use. New designs and advanced electric motors will reduce energy consumption while maintaining high levels of performance. Energy recovery systems will be implemented, taking advantage of pump duty cycles to further reduce waste. These improvements will help contain operating costs and reduce environmental impact.

Intelligent pumps

Pumps will become increasingly intelligent through the integration of advanced sensors and automated control systems. They will be able to autonomously monitor operating conditions, adapting performance to needs in real time. With the use of predictive algorithms and artificial intelligence, these pumps will detect potential failures before they occur, dramatically reducing downtime and extending their service life.

Internet of Things (IoT)

The IoT will transform piston pumps into interconnected devices that can communicate with each other and with other machinery. With connectivity, remote monitoring systems will become the norm, enabling more efficient and timely management. In addition, predictive maintenance will become increasingly common, optimizing operational processes and minimizing downtime. The ability to collect real-time data will improve the effectiveness of operations, ensuring targeted and rapid interventions.

Sustainability

Sustainability will play a crucial role in the development of piston pumps. The design of the pumps will be geared toward minimizing waste and reducing emissions. In addition, the longevity of the pumps will increase through the use of modular components and advanced technologies, helping to reduce their overall environmental impact.

Security

Piston pumps will be equipped with increasingly advanced safety technologies. Sensors capable of detecting operational anomalies and automatic emergency shutdown systems will provide an unprecedented level of safety. Continuous monitoring will reduce the risk of sudden failures, increasing the overall reliability of the pumps.

Cost reduction

Cost reduction will be a priority through automation and predictive maintenance. Pumps will require less frequent interventions and be less prone to failure, resulting in lower expenses associated with extraordinary maintenance.

Conclusions and the role of Hawk

In a constantly changing industrial landscape, piston pump innovation will continue to redefine the parameters of efficiency, sustainability and safety. From advanced materials to smart solutions integrated with IoT, the piston pumps of the future will offer increasing benefits for those seeking reliability and optimal performance.

At Hawk, we are committed to staying at the forefront of this field, adopting the most innovative technologies to ensure that our customers always have access to the most advanced solutions. With our constant focus on new trends and cutting-edge product development, we are poised to lead the future of piston pumps, delivering quality, efficiency and safety in every project. Contact us now for information!

Share this Article