Maintenance of piston pumps: our tips

Piston pumps are an essential tool for those working in the industrial and professional sectors, especially in high-pressure washing. However, to ensure optimal performance and long equipment life, it is essential to follow regular maintenance.

This article will provide an overview of how to properly preserve piston pumps, from the basics of operation to practical tips for avoiding common problems to maintain pump efficiency and prevent costly damage.

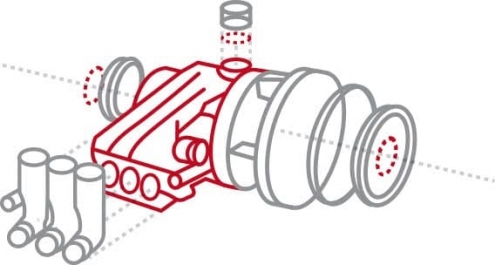

How a piston pump works

Piston pumps are designed to generate constant pressure by reciprocating movement of one or more pistons inside cylinders. During each cycle, the piston creates a vacuum in the cylinder, drawing liquid through a suction valve. When the piston begins the pushing phase, the liquid is expelled at high pressure through a delivery valve.

The main components of a pump are:

- Pistons: through their action the movement of liquid flow is generated.

- Cylinders: main body of the pump within which the pistons move.

- Suction and delivery valves: regulate the flow of liquid in and out.

- Seals: ensure a tight seal, preventing leakage and protecting internal components.

Maintenance tips for piston pumps

Careful and regular maintenance of the piston pump can greatly reduce the risk of failure and repair costs.

By following some practical tips you can keep your pumps in top condition.

- Daily inspection for oil or water leaks: every day it is advisable to perform a visual inspection to make sure there are no oil or water leaks. These simple, quick but essential checks help prevent major problems and ensure optimal pump operation.

- Daily check of oil level and quality: check the oil level using the visual oil level gauge. Ensure that the oil is always the right amount to avoid wear and tear on internal mechanical parts.

- Filter cleaning: regularly check and clean filters, especially those in the suction circuit, to make sure they are not clogged. A clean filter prevents debris and solid particles from damaging internal components such as valves and pistons, thus ensuring a steady flow of water.

- Checking fittings and piping: critical activity to detect any signs of aging such as bulges or abrasions and water leaks that can reduce pump efficiency and compromise system safety. Tighten fittings and replace worn piping when necessary.

- Scheduled oil change: perform the first oil change after 50 hours of operation and every 500 hours thereafter. This interval may vary depending on operating conditions. When changing, place the pump on level ground, remove the drain plug to completely drain the used oil, then fill with new oil to the indicated level. Be sure to use only the suggested oil as indicated on the pump nameplate to ensure optimum performance and reduce component wear. Disposal must be in accordance with current environmental protection regulations.

- Checking pump fastening: regularly check that the pump fastening screws are tight. Vibration or movement during operation can loosen them, leading to loss of stability and potentially structural damage.

- Preventive maintenance on seals: if worn they compromise the seal of the piston pump, causing pressure drops and/or water leaks increasing the risk of failure. Good practice suggests replacing seals every 1,000 hours of operation or in case of leaks.

- Inspect the valves: they must open and close properly to maintain proper pressure. In any case, we recommend replacing them every 1,500 hours.

- Adapt maintenance to the work cycle: the frequency of maintenance work should be calibrated according to the actual use of the pump. In the case of particularly heavy or wear-intensive uses, such as intensive use or in harsh environmental conditions, it is advisable to anticipate checks and replacements compared to standard intervals. Timely maintenance in such cases prevents failures and ensures longer component life.

By following these simple but important steps, you can extend the operating life of the pump and improve its performance. Regular maintenance not only protects your investment, but also ensures greater productivity and safety when using these tools.

Conclusion: Hawk as an ideal partner for piston pump maintenance and service

Relying on an experienced partner like Hawk means you can count on quality products and qualified technical support for every stage of maintenance.

We are a leader in the manufacture and sale of high-pressure piston pumps for industrial washing, and our commitment is to ensure our customers reliable equipment, reliable spare parts for specific models, and support services.

If you want to optimize the use of your piston pump and have maximum performance, contact us for more information.

Share this Article