Hydro-sandblasting and the role of piston pumps: comprehensive overview

Hydro-sandblasting is an essential cleaning methodology in various industrial and professional sectors, providing precise, efficient and environmentally friendly results. At the heart of this technology are piston pumps, devices that make it possible to achieve the high pressures required for effective removal of dirt, scale and coatings.

But why is Hydro-sandblasting the preferred choice today over traditional sandblasting? What is the key role of Hawk pumps in this process? With this article, we at Hawk will compare these two technologies and delve into the role of piston pumps, essential tools for ensuring optimal performance.

Hydro-sandblasting: what it is, what it is used for, and the differences with sandblasting

Hydro-sandblasting is an industrial cleaning technique that uses the power of high-pressure water to remove dirt, scale, and coatings from various surfaces. This method, often supplemented with abrasives such as baking soda, sand, or glass granules, provides a more controlled cleaning action than traditional sandblasting, reducing the risk of damage to treated materials.

Unlike sandblasting, which uses compressed air to project solid abrasives, Hydro-sandblasting harnesses the kinetic energy of water, which is pressurized and hurled onto the surface with sufficient force to dislodge contaminants and unwanted layers. The use of water, whether or not combined with abrasives, limits dust dispersion and minimizes waste generation, making the process safer and more environmentally friendly.

Hydro-sandblasting is distinguished by its ability to adapt to different surfaces and levels of contamination, allowing targeted interventions on both robust materials, such as steel and concrete, and more delicate surfaces, without compromising their structural integrity.

The fields of application of Hydro-sandblasting

Thus, it is clear that this activity is incredibly versatile and lends itself to many applications:

- Heavy industry: cleaning of machinery, piping and tanks.

- Marine industry: maintenance of hulls, removal of algae and marine deposits.

- Construction: cleaning facades, flooring and concrete structures.

The key role of piston pumps in Hydro-sandblasting

Piston pumps are fundamental devices for hydroseeding, as they are designed to transform mechanical energy into hydraulic energy.

Compared to the compressors used in sandblasting, reciprocating pumps offer superior control over water flow, ensuring a more precise and consistent spray pattern. This feature allows Hydro-sandblasting to adapt to different operational needs without compromising the integrity of treated surfaces.

The high pressures achieved by piston pumps enable them to remove even the toughest coatings, such as industrial paints and marine fouling, without generating hazardous dust. In addition, pumps designed for Hydro-sandblasting are made of materials that are resistant to corrosion and wear, offering a longer operating life than conventional sandblasting systems.

Conclusions and Hawk's role with Hydro-sandblasting

Compared to traditional sandblasting, Hydro-sandblasting has established itself as an indispensable technology in many industries because of its effectiveness, safety and versatility. However, to take full advantage of the benefits, it is essential to rely on quality and reliable high-pressure pumps, such as those made by us at Hawk, designed to meet the needs of Hydro-sandblasting.

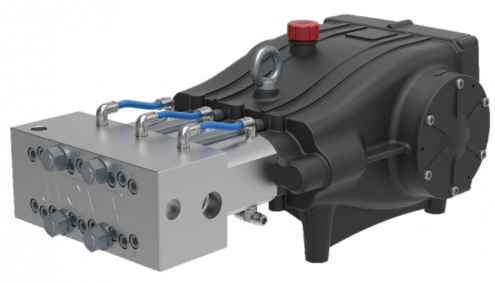

GXX series piston pumps, for example, are capable of operating at a maximum pressure of 1000 bar, with a flow rate of up to 23.8 liters per minute. These features make them ideal for removing rust, paint and stubborn scale on metal and other hard surfaces. Robust construction and the use of durable materials ensure long life and consistent efficiency.

On the other hand, TXX series pumps offer a maximum operating pressure of 1000 bar and a flow rate of up to 36 liters per minute. This increased flow capacity makes it particularly suitable for applications requiring intensive and rapid cleaning of large surfaces or removal of particularly tough coatings. The TXX series is designed to operate efficiently even under the most demanding conditions, ensuring optimal results in Hydro-sandblasting.

Both series are built to withstand water temperatures up to 65°C, ensuring versatility in a variety of operating conditions. The build quality and technical specifications of the GXX and TXX pumps make them indispensable tools for professionals seeking effective and durable solutions in Hydro-sandblasting.

For more details on the technical specifications and applications of our Hydro-sandblasting piston pumps, please contact us. Our team is ready to answer all your questions and guide you in choosing the ideal solution.

Share this Article